Call Us Now

089 242 9368

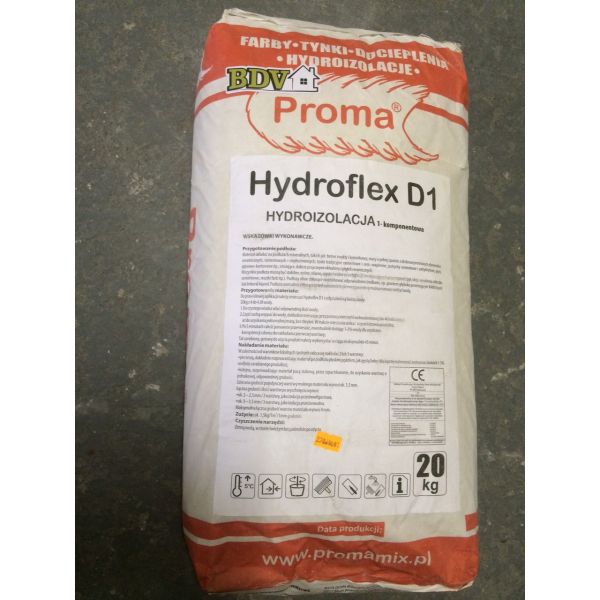

PROMA Tanking System D1 - ONE COMPONENT 20kg

€79.95

€65.00

Tanking Membrane is a flexible, one-component, cementitious sealing slurry used to produce crack-bridging waterproof membranes (for composite systems comprising membrane and tile finish). This waterproof membrane can be used on balconies, patios, in showers, washrooms, wetrooms, toilets and swimming pools, applied prior to tiling (as part of composite system with membrane and tile finish).

Availability:

In stock

SKU

100-D1 TANKING

- Buy 2 for €73.80 €60.00 each and save 8%

Tanking Membrane is a flexible, one-component, cementitious sealing slurry used to produce crack-bridging waterproof membranes (for composite systems comprising membrane and tile finish).

This waterproof membrane can be used on balconies, patios, in showers, washrooms, wetrooms, toilets and swimming pools, applied prior to tiling (as part of composite system with membrane and tile finish).

For refurbishment of solid, strong existing tile coverings on balconies and patios.

Provides flexible, crack-bridging waterproof barrier for protection/preservation of structures and building elements.

For indoor and outdoor use

• For walls and floors

• Vapour-permeable

• For balconies and patios, for damp and wet areas

• Ideal for waterproofing fountains and spring catchments

• For roller, spatula, brush application Suitable

Substrates: Mineral substrates, including concrete, lightweight concrete, aerated concrete, cement and lime/ cement render, gypsum plasterboard and gypsum fibreboard, plywood, osb boards, cement boards, renders made from masonry cement, plane, ,concrete screeds, calcium sulphate-based (anhydrite and self-levelling anhydrite) screeds & boars, board subfloors, existing ceramic coverings.

Priming BDV PROMAG K primer: Cement screeds, calcium sulphate-based (anhydrite and self-levelling anhydrite) screeds, board subfloors, paperless gypsum wall panels, gypsum plasterboard/joints and filler, gypsum fibreboard, gypsum plaster, high- or variable-suction (interior) aerated concrete, cement and lime/ cement render, renders made from masonry cement, flush-jointed masonry. Allowance should be made for approx. 12 hours drying time for gypsum-based substrates pretreated with BDV PROMAG K primer.

Application Fill clean container with 5.2 – 8.0 ltr water, depending on application method, add 20 kg PROMAG tanking system D1 (alternatively, to 2.6 – 4.0 ltr water, add 10 kg PROMAG tanking system D1 and mix mechanically to homogeneous, lump free consistency.

After 3-5 minutes maturing time, remix thoroughly. Trowel, brush, roll or spray on two full-cover coats of PROMAG tanking system D1 (1.3 mm wet coat thickness in either case) to slightly damp substrate.

Apply second coat only after first coat has achieved adequate strength/walkability and has been inspected for defects.

PROMAG tanking system D1 one component flexible sealing slurry is recommended for waterproof bonding at laps with PROMAG HYDROFLEX SEALING TAPES and PROMAG HYDROFLEX SEALING INTERNAL & EXTERNAL CORNERS.

Storage Approx. 24 months, subject to storage on pallet in dry conditions in original unopened containers.

This waterproof membrane can be used on balconies, patios, in showers, washrooms, wetrooms, toilets and swimming pools, applied prior to tiling (as part of composite system with membrane and tile finish).

For refurbishment of solid, strong existing tile coverings on balconies and patios.

Provides flexible, crack-bridging waterproof barrier for protection/preservation of structures and building elements.

For indoor and outdoor use

• For walls and floors

• Vapour-permeable

• For balconies and patios, for damp and wet areas

• Ideal for waterproofing fountains and spring catchments

• For roller, spatula, brush application Suitable

Substrates: Mineral substrates, including concrete, lightweight concrete, aerated concrete, cement and lime/ cement render, gypsum plasterboard and gypsum fibreboard, plywood, osb boards, cement boards, renders made from masonry cement, plane, ,concrete screeds, calcium sulphate-based (anhydrite and self-levelling anhydrite) screeds & boars, board subfloors, existing ceramic coverings.

Priming BDV PROMAG K primer: Cement screeds, calcium sulphate-based (anhydrite and self-levelling anhydrite) screeds, board subfloors, paperless gypsum wall panels, gypsum plasterboard/joints and filler, gypsum fibreboard, gypsum plaster, high- or variable-suction (interior) aerated concrete, cement and lime/ cement render, renders made from masonry cement, flush-jointed masonry. Allowance should be made for approx. 12 hours drying time for gypsum-based substrates pretreated with BDV PROMAG K primer.

Application Fill clean container with 5.2 – 8.0 ltr water, depending on application method, add 20 kg PROMAG tanking system D1 (alternatively, to 2.6 – 4.0 ltr water, add 10 kg PROMAG tanking system D1 and mix mechanically to homogeneous, lump free consistency.

After 3-5 minutes maturing time, remix thoroughly. Trowel, brush, roll or spray on two full-cover coats of PROMAG tanking system D1 (1.3 mm wet coat thickness in either case) to slightly damp substrate.

Apply second coat only after first coat has achieved adequate strength/walkability and has been inspected for defects.

PROMAG tanking system D1 one component flexible sealing slurry is recommended for waterproof bonding at laps with PROMAG HYDROFLEX SEALING TAPES and PROMAG HYDROFLEX SEALING INTERNAL & EXTERNAL CORNERS.

Storage Approx. 24 months, subject to storage on pallet in dry conditions in original unopened containers.

| Product Code | 100-D1 TANKING |

|---|

Delivery Update Notice

We’re in the middle of switching couriers after our previous provider closed.

We’re updating our courier service, so standard delivery may take

5–20 business days.

Pallet deliveries remain unchanged and will continue to arrive within

2–3 business days.